Continuous innovation is in our DNA

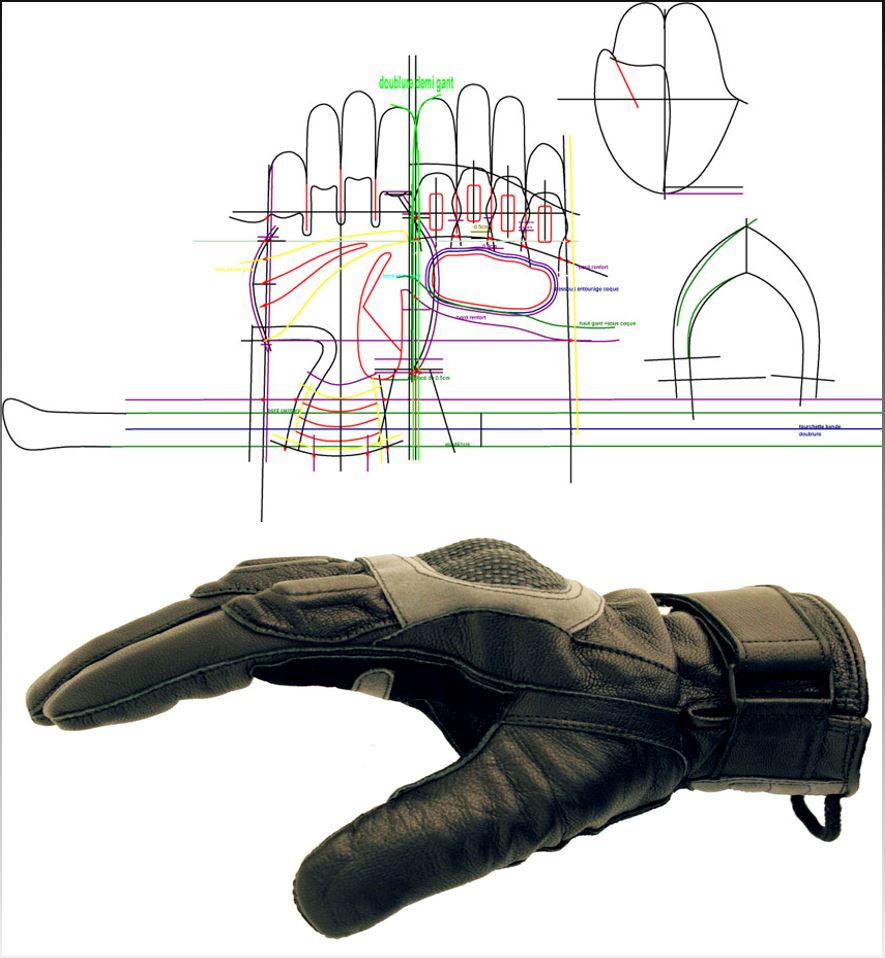

GM Tech is a benchmark of industrial know-how in the manufacture of innovative, high-performance specialist gloves in France and abroad. Our gloves are for the exclusive use of law enforcement and security force professionals , and are not simply additions to the range of a multi-product, generalist manufacturer. They are designed for specific operations and in close collaboration with various intervention agencies, by collecting information on their precise needs on the ground.

Innovation is part of our culture. We are constantly researching ways to combine technical fibres, high-tech materials and state-of-the-art components (Armalith® , D3O® etc.) to improve our models. We process tried-and-tested natural and synthetic raw materials (tactile leather, Nomex® , Kevlar® , Kermel® etc.) and combine them with raw materials obtained through our technical and technological partnerships with major manufacturers (Dassault, Thales, Airbus Helicopters etc.).

GM Tech is also constantly striving to innovate, and we take care to protect our research: In 2014, the company filed a patent for “fast-rope gloves†that are touchscreen and weapon-compatible, which makes the gloves dual-use. This innovation eliminates the need for law enforcement and security force professionals to carry two pairs of gloves for different purposes, thereby reducing the load carried on the ground.

GM Tech also offers other innovative models to meet other specific needs, including discreet cut-resistant gloves that can be worn with a business suit, non-flammable tactile pilot gloves that work on tablets despite their UV protection and Level 5 cut-resistant gloves in accordance with EN 388 without external palm reinforcement.

The range of materials used for our different models of gloves is extremely wide in order to suit a number of uses: descending ropes, protecting against fire, cuts or abrasions, repelling water etc. All our materials undergo physical and chemical tests to guarantee their performance and safety.

Furthermore, the manufacture of innovative quality products also requires considerable experience and a thorough understanding of the relevant European and international standards, to ensure that all models are safe and suitable for their different uses by different intervention agencies.